Software

With its intuitive and data-driven design, our software provides extended functionality at your fingertips.

Our software is designed in-house, customized specifically for our AM1 printer.

Our software's features present optimal solutions focusing on enhancing the quality of your print. See for yourself:

Dashboard

Designed in-house, Cosine’s dashboard operates seamlessly with the our AM1 3D printer.

The large touch screen interface allows for easier navigation and straightforward application. Now, any user can become proficient in 3D printing.

Materials database

We have over 800 materials in our very own database.

We work with filament and resin companies to add new materials to our database everyday. Everyone in our network immediately gains access to existing data or new data that we discover.

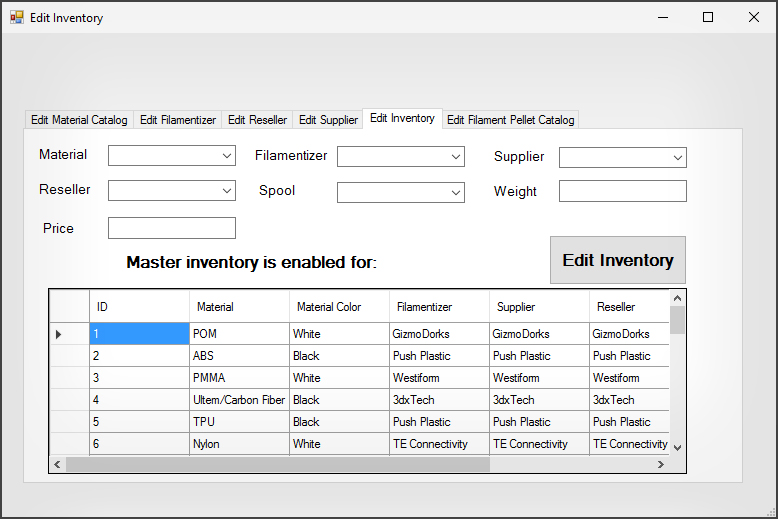

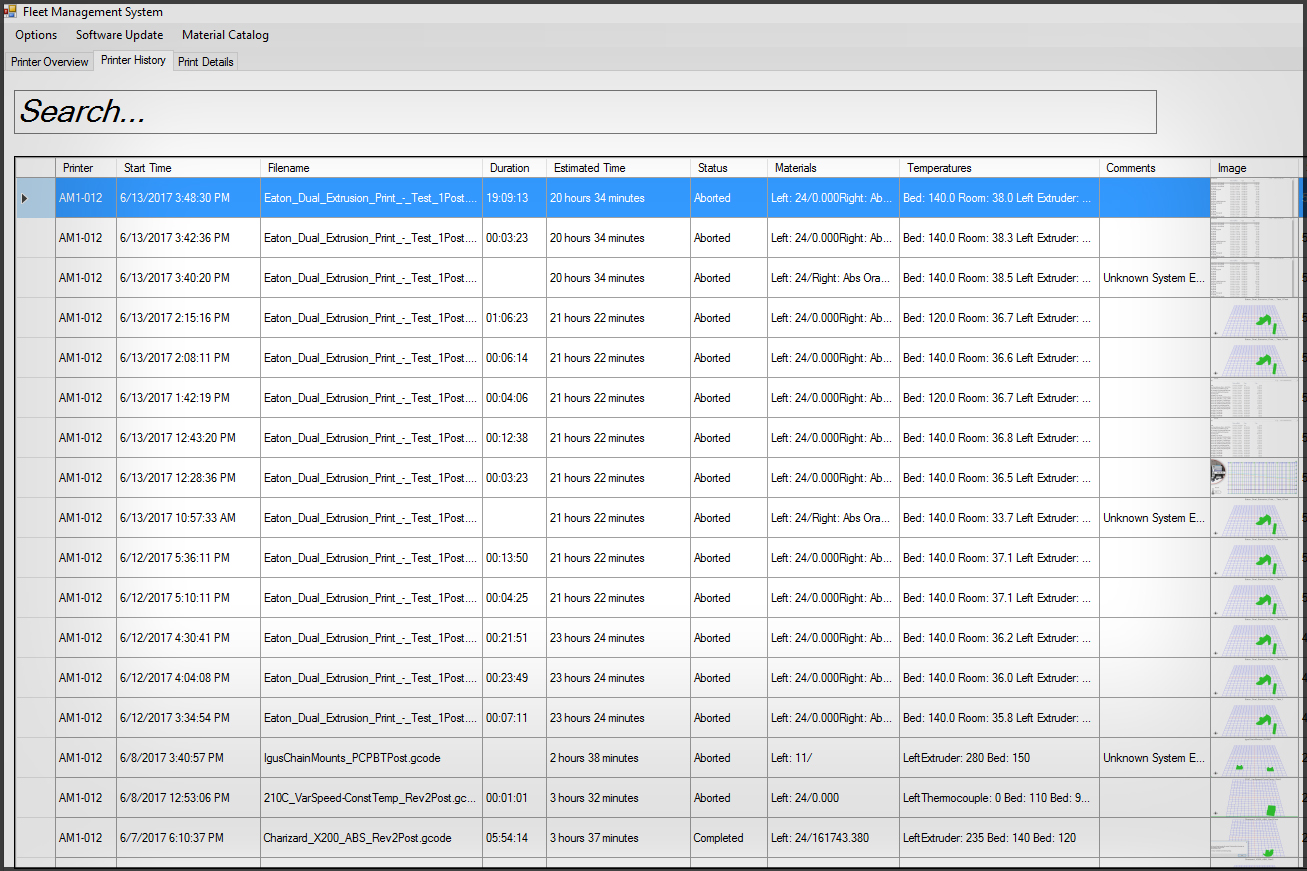

Take Command with

Cosine’s Fleet Manager

Cosine’s custom Fleet Manager creates a convenient place for our users to manage multiple machines all in one place.

This program includes part traceability that enables users to trace settings from the material used, print settings involved, and where the part goes. In addition to tracking, the Fleet Manager runs reports:

number of parts printed

print success rate

amount of filament used.

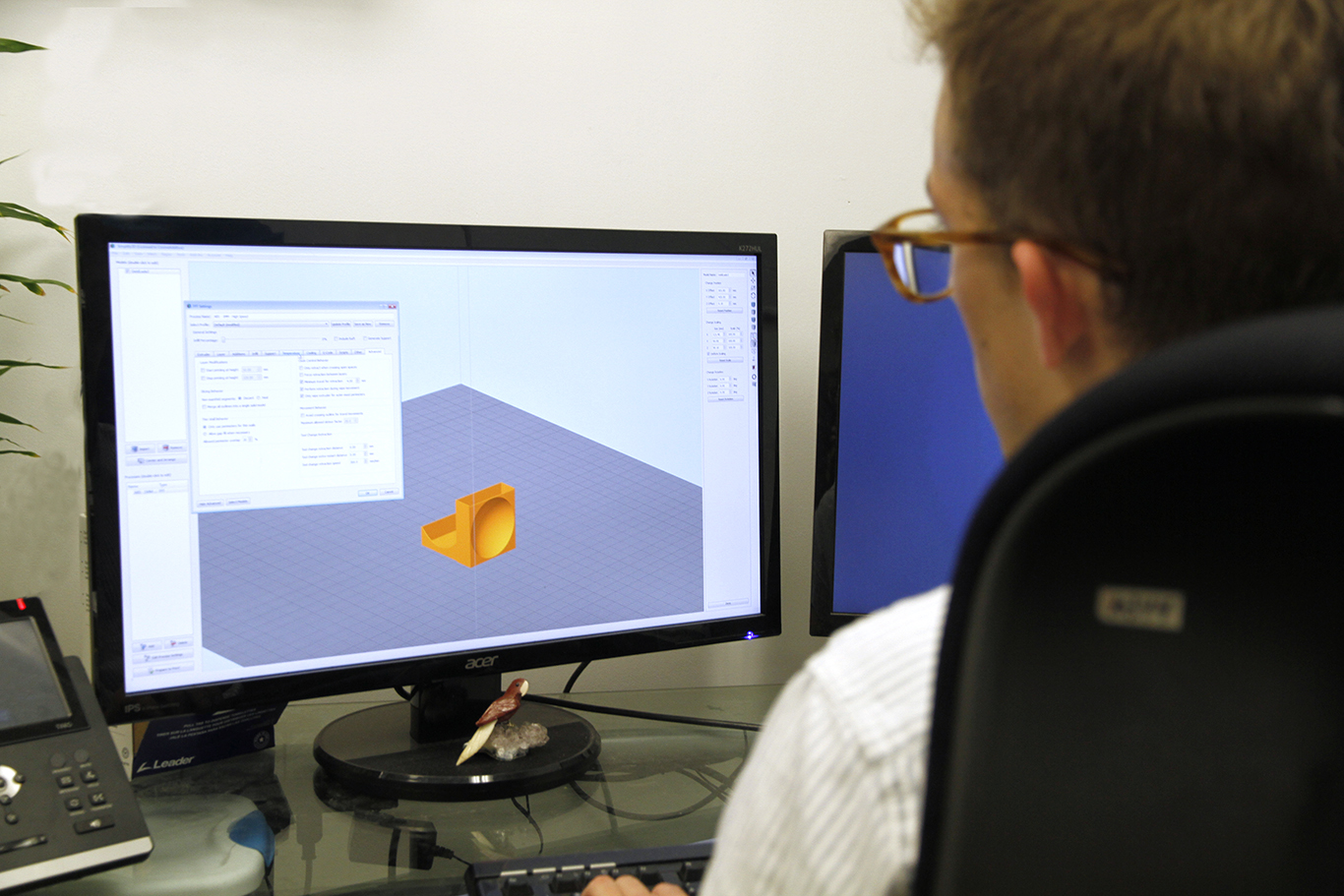

SLICER

Most slicers weren’t created for fast, industrial-sized 3D printers, so we're creating our own.

Cosine’s slicer automatically syncs optimal temperature and speed settings according to the material. Since we designed it ourselves, we can customize it based on your needs and continuous improvements.

G-Code post processing

Cosine’s post-processing is an intermediate step between slicer & printer. Using optimization equations, our software alters the g-code to produce the best print results.

Dynamic Prime

Extra extrusion is added to replace material lost during rapid travel moves, where excess oozing occurs.

Printing without dynamic priming (left) vs. printing with dynamic priming (right)

Arc conversion

High polyline curves are translated into arcs, resulting in a smoother finish and faster prints.

Tool path without arc conversion vs. New path (orange) with arc conversion (right)

Minimum line segment

G-code is filtered to remove unimportant details smaller than the nozzle diameter.

Tool path without minimum line segment (left) vs.

new path (orange) with minimum threshold set to .15 mm (right)

Automatic temperature control

Your extruder’s temperature is driven by Cosine’s Material Database based on the volume of material extruded. This mitigates material degradation, resulting in a cleaner finish and stronger part.