A lot of traditional 3D printers utilize a series of belts and motors to produce motion. Consumer grade FFF (Fused Filament Fabrication) printers use belt-driven movement for the X and Y, along with a ball-screw system for the Z axis. We began looking internally for alternatives for our own belt-drive system, and under the same operating conditions, chains were found to be cheaper, easier to order with shorter lead-times, and a lot more compatible hardware that can be found off the shelf. On the AM1 line of machines, the Y bridge is an aluminum billet construction with robust, industrial grade extruder tools. This can add substantial load to the Z axis, which shortens the lifespan of the belt. Also, when compared to chain systems, belt systems require more hardware to install and maintain.

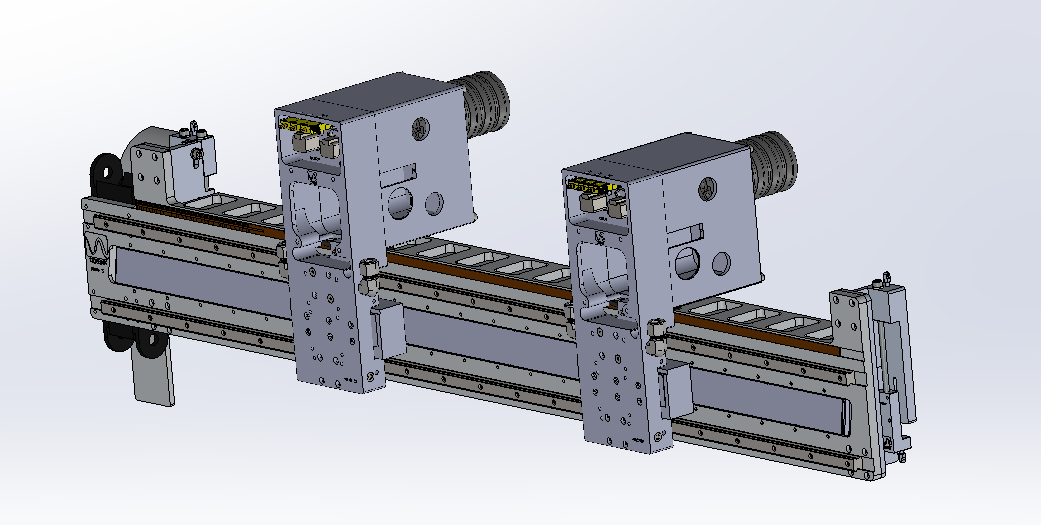

Cosine Y-Bridge Complete Assembly

Since switching to a chain drive for the Z, we have seen an increase in the lifespan of the system, with significantly less deflection under load. This improves the accuracy of the Z axis during printing and produces more consistent layers throughout prints. Belts also require periodic maintenance to re-tension the system as the belts plastically deform over time, an issue not seen with belt driven systems.

Although it does not happen often, some belt systems have been known to snap due to an excess of force acting on the Z system, especially when the belts are older and not maintained as well. This cripples the system and translates to a list repairs and maintenance. From in-house testing, the chain system can withstand a much larger amount of stress and force than any belt system of similar size; making it so that the chain system is not a likely point of failure.