We wanted to highlight some of our new features in the blog, one of which is the Advanced/Extended Work Coordinates System.

If you have a background in the CNC world, then you will be well acquainted with Work Coordinate Systems, and if you are familiar with Cosine’s machines, then you know that we have been utilizing Work Coordinate Systems already. For the uninitiated, I will provide a brief overview.

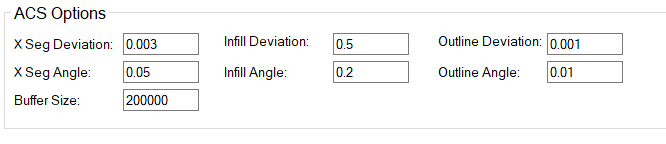

A Work Coordinate System is essentially a reference point for the origin of a machine. If we change the Work Coordinate System, we change where the origin is. Changing the origin allows us to move where on the bed a part is printed. This is helpful in many situations, one of which is that you just finished a print on one section of the bed, and you want to print the same thing but on a different section of the bed. Instead of reslicing the print so that it is moved to the different part on the bed, you would just change your Work Coordinate System and then proceed with your print.

So that is a brief overview of what a Work Coordinate System (or WCS) is. Now we will discuss what we call Advanced Work Coordinate Systems.

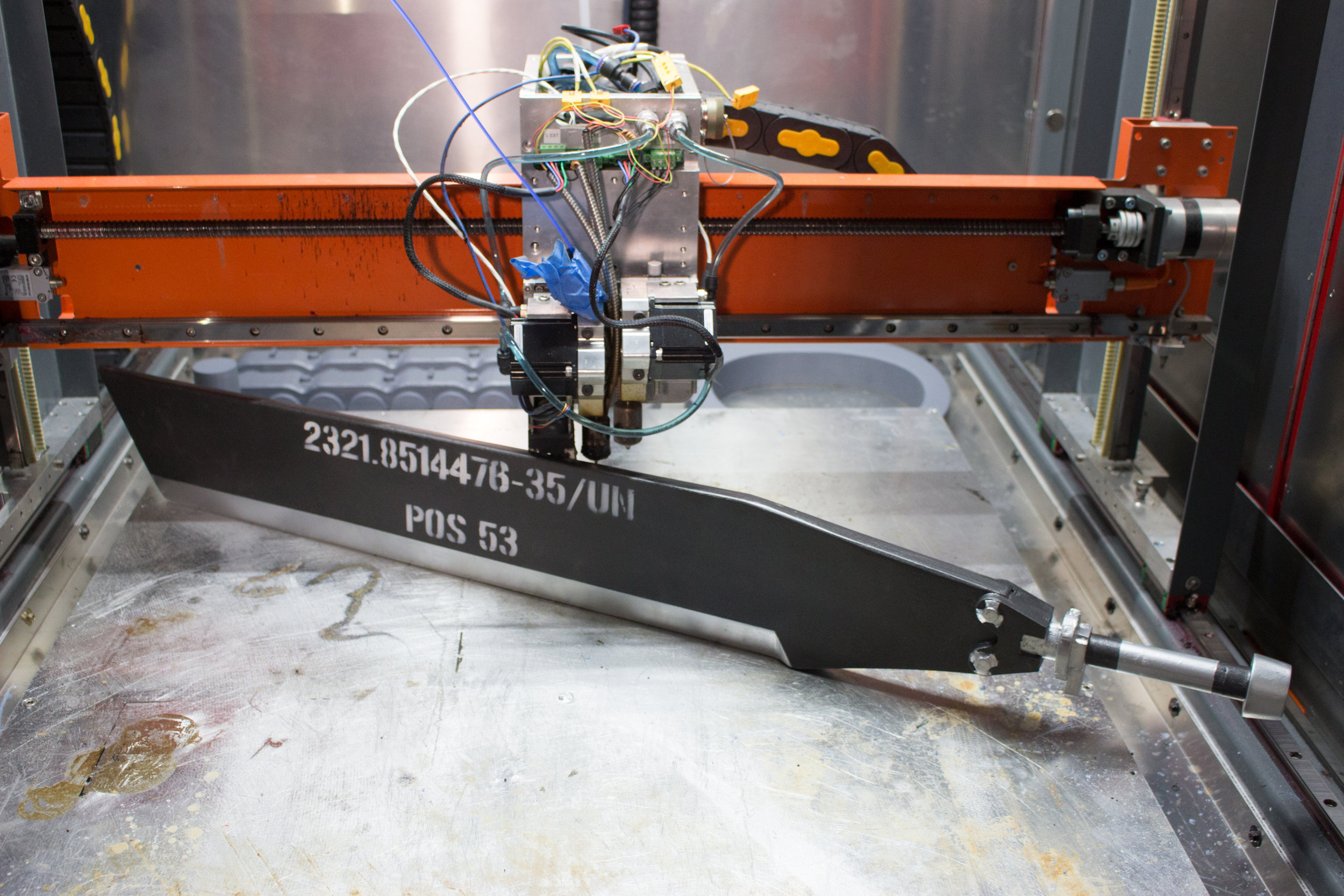

When we previously used WCSs, we would have only a single WCS that would be overwritten upon each change. Now we can choose from up to 9 different WCSs, that we can modify individually to fit our needs. The 0 index WCS is what is known as the Machine Coordinate System because it cannot be edited by the user, and it always has offsets of 0. Also, as mentioned previously, we were able to only change the offsets for the X, Y, and Z. With the new Advanced Work Coordinate Systems, we can now also change the offsets for the A, B, and C axes (only relevant for machines that have those extra axes), as well as the Yaw, Pitch, and Roll.

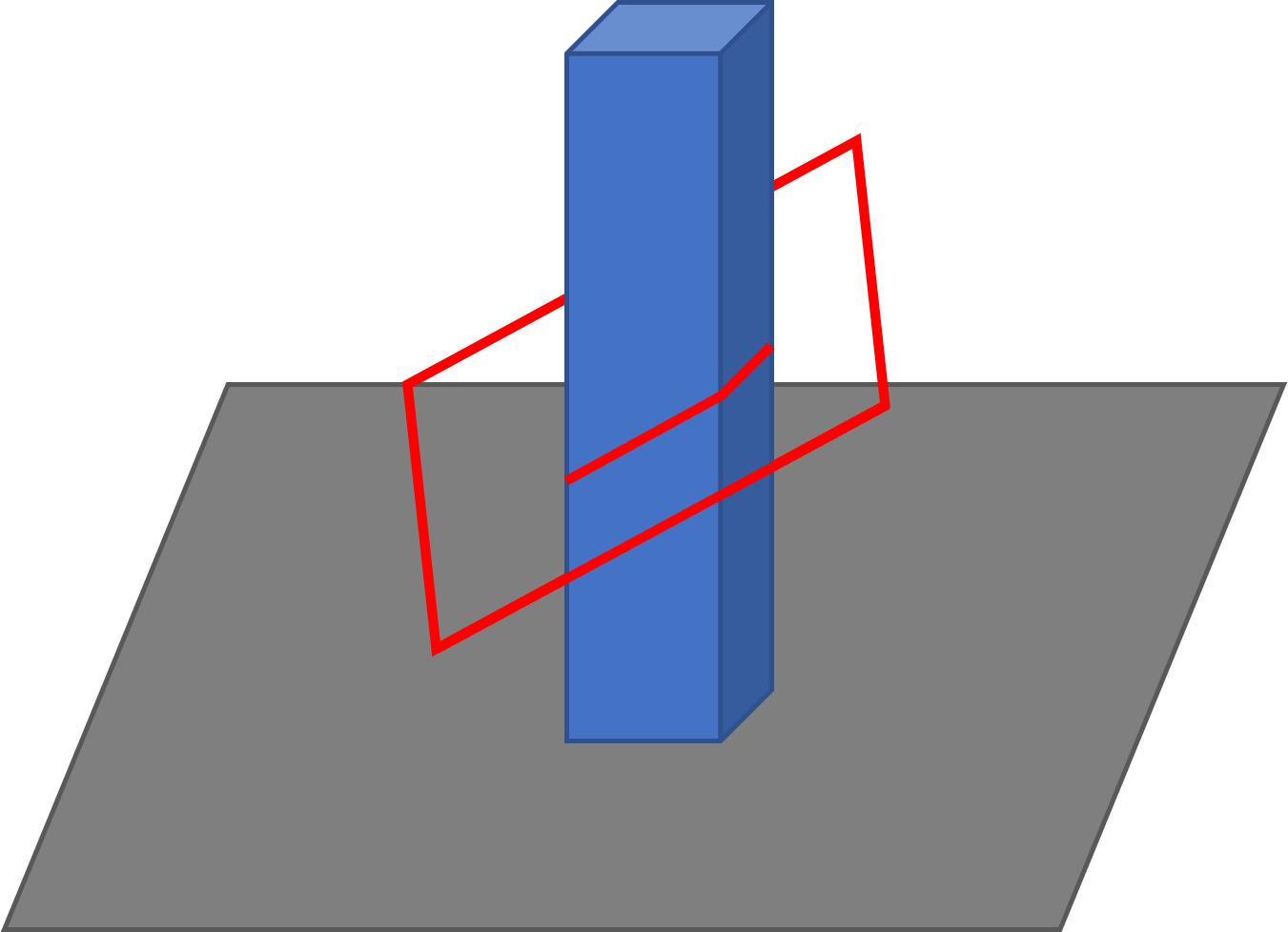

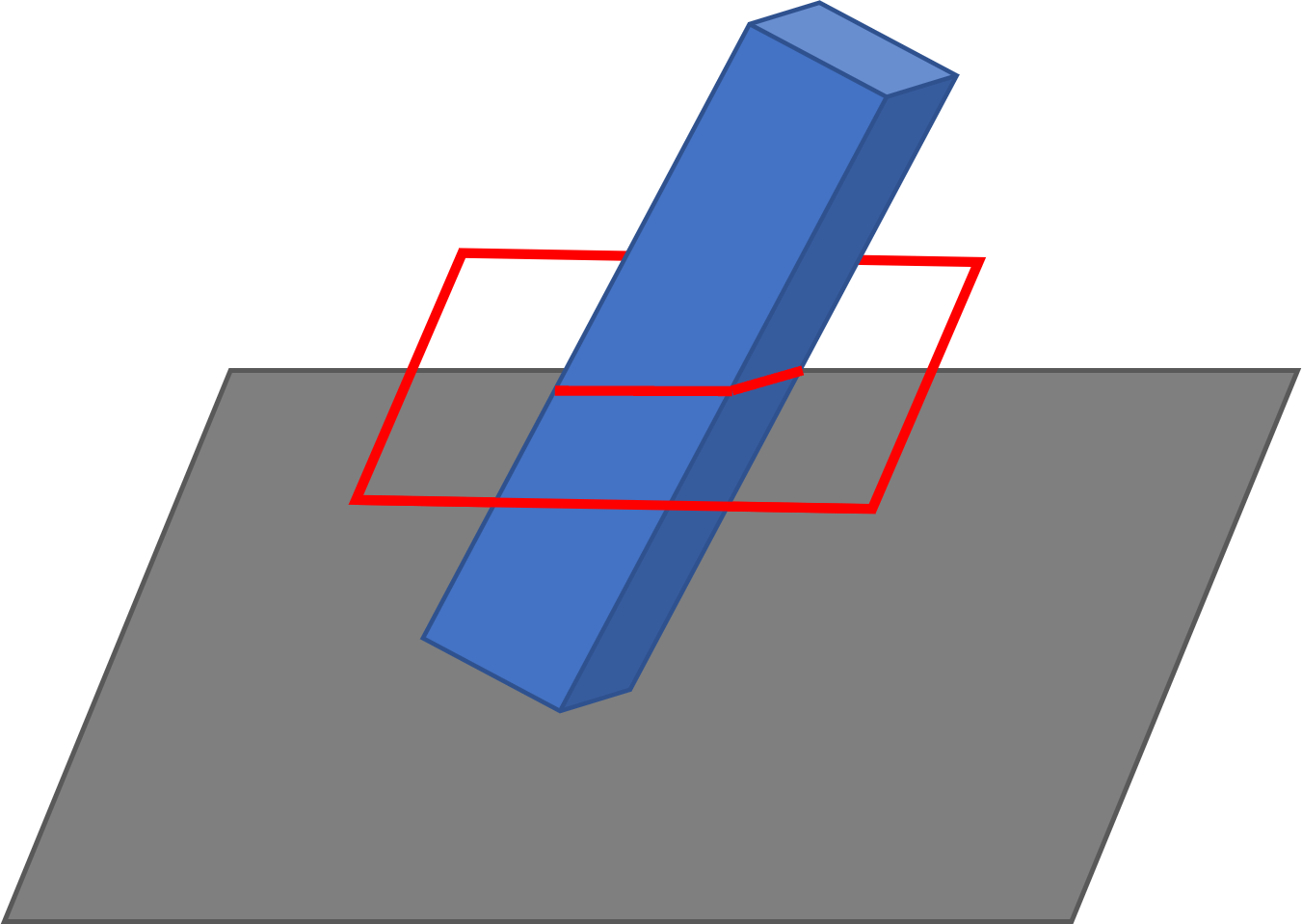

The offsets for the Pitch, Yaw, and Roll offsets enable us to do more things that we previously were not able to. When these offsets are changed (their units are degrees), you can rotate around the X, Y, and Z axes by the degree offset that you set. This allows us to do things such as align the coordinate system to an object that you are printing on or to account for some error in the print surface we are printing on, such as if the print surface is misaligned in the y axis all without having to modify the g-code we are printing.

Advanced Work Coordinate Systems open up many more printing possibilities and we are excited to see how our customers end up using this feature!

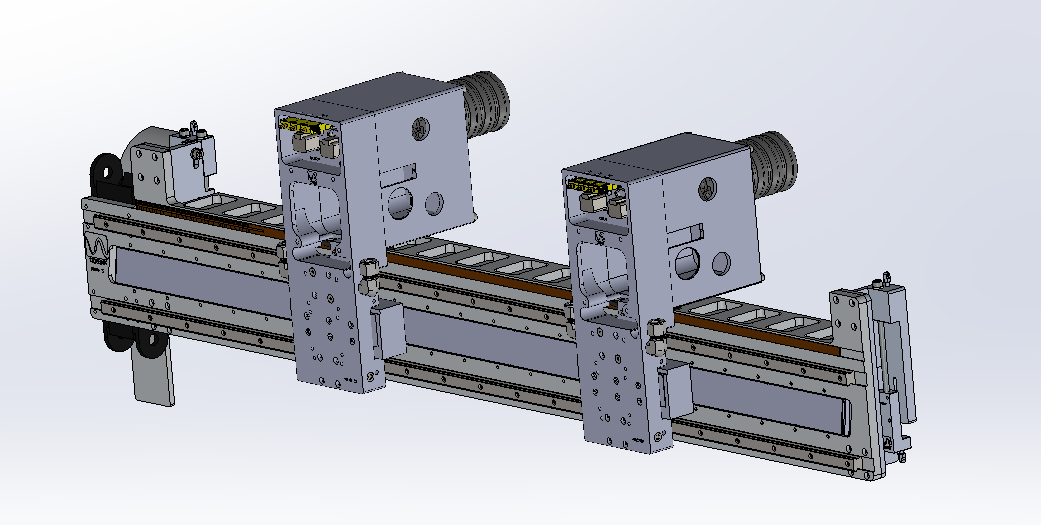

![m54mnew2[2].jpg](https://images.squarespace-cdn.com/content/v1/55627b1be4b020bb00b2d516/1562867303054-HQ2KAFMEPP5PYPKT3Z0H/m54mnew2%5B2%5D.jpg)